Manufacturing

We have developed and mass-produced front ends to allow for the automated loading and discharge of wafers between fab tools and FOUPs.

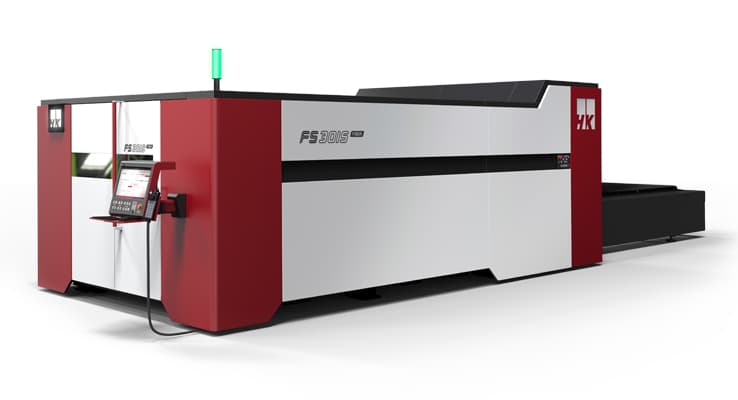

The unique capabilities of our large-format five-axis machining facility and metal fabrication are used around the world for semiconductors, medical equipment, and other high-demand applications.